Subsidiary Parts

We self-produce parts necessary for deck and fence.We produce parts for fence including normal clip, horizontal clip, deck clip such as femoral extended one-touch clip without screw, column upper cap, lower cap (squat), flexible bracket, and fixed bracket.

Coffee Sludge Plastic Composite

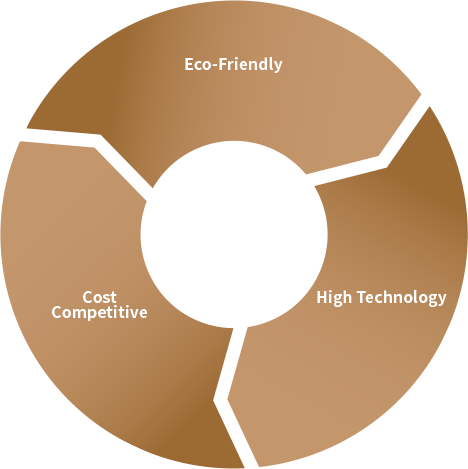

Eco-friendly, easily accessible, and safe product at low price point

-

Eco-friendly

Circulates & recycles waste resources -

Cost Competitive

Produces products with low carbon, low pollution at low price -

High Technology

Technology that produces products that can be used in daily life

as a technology that can be commercialized immediately

High-Technology

Proces Chart of Coffee grounds Plastic Composite

Collects coffee grounds - dry - blend(material blend) - Compounding (manufacturing pellet) - Profile injection (product molding) - Surface processing

Eco-Friendly

100% Recyclable

= Coffee grounds + eco-friendly Bio-Mass Resin= Coffee Sludge Plastic Composite

-

1. Reduced carbon emission

- Reduces CO2 and methane gas occured when burn or bury coffee grounds

- Reduced damage on tree due to logging by using coffee grounds as an alternative of wood flour -

2. Resource saving

- Saves cost of standard plastic garbage bag and bury with coffee grounds

- Saves foreign currency with reduced import of wood flour required for timber products -

3. Buliding system of waste resource circulation

- If fulfilled its usage purpose, it is possible to reuse by collecting and griding without any harmful substances emitted

or used during this process

- Possible to dry and re-use the entire amount of coffee grounds discarded in Korea

Cost Competitive

Cost is the most important part of waste resource recycling

- if the cost of recycling is higher than the cost of waste process, the process cost will be raised higher than the existing products,which will eventually be eliminated in the sales competition in the market.

- Short and instant process till the final product

| Product | Country of origin | Process method | Side effects | Import | Level | Post-processing | Post-management | Pest control | Note |

|---|---|---|---|---|---|---|---|---|---|

| Synthetic material (Wood flour) |

Import/Domestic | Logging | Environmental issues | Wood flour mostly imported |

Moderate | Unnecessary | Simple cleaning | No | Wood flour mostly imported |

| Synthetic material (Coffee grounds) |

Domestic discharge | Recycling waste | No environmental issues | No import |

Moderate | Unnecessary | Simple cleaning | No | Increased raw materials due to high demand of coffee |

| Treated timber | Domestic/Import | Logging | No environmental issues | Premium timbers mostly imported |

Moderate | Necessary | Self-oil stain | Yes | Environmental pollution due to chemical process |